Safety

- Reduces stored energy from 8000+ lbs. to less than 300 lbs.*

- Eliminates nearly all line-of-fire risks

*Typically 11 lbs. between units

Efficiency

- Reduces installation time by an average of 35%

- Can make pulls that were impossible using conventional pull techniques

- Can eliminate splices in the middle of cable runs

Cost

- Greatly reduces risks of damage to cable

- Nearly eliminates Side Wall Pressure (SWP), increasing cable life

Pull Smarter

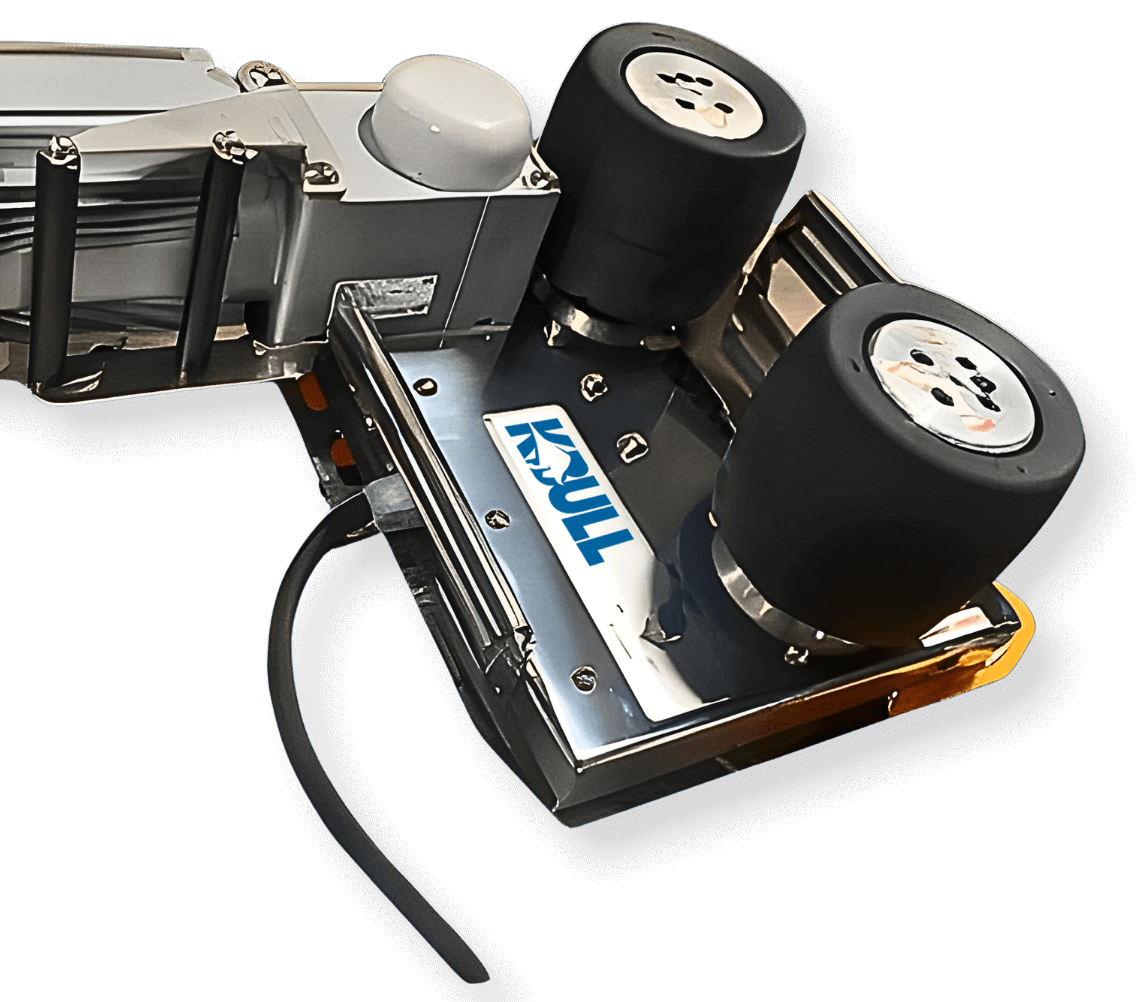

KBULL System

- Faster progress with smaller crew

- No heavy rigging

- Multiple motors pulling at once

- Reduces tension across every section

- Pulls several cables simultaneously

Not Harder

Traditional Tugging

- Bigger crew, longer hours

- Heavy rigging required

- Pulled by hand or winch

- High tension with increased risk

- Single-cable capability

Technical Specifications

Cable Diameter:

Can pull cable up to

4” in diameter

(3/C 15kv 750 CLX)

Unit Motor:

~400W

System Requirements:

3-Phase, 60A, 208/240V per controller

Compatibilities:

Greenlee, Current Tool, and other systems

Clearance:

Approved for operations in classified areas with a “Hot Work” permit

Our Process

Our KBULL system pairs our qualified team with cutting-edge technology to stay ahead of the curve on each and every installation project.

Our process is carefully designed with safety in mind and allows us to deliver unmatched cable installation services to job sites across the region.

Project Design

- Pull Assessment

- Pull Report

- Pull Diagram

- Pull Plan Review

- Pre-Installation Checklist

Project Execution

- KBULL Safety Meeting

- System Setup

- Project Safety Meeting

- Cable Installation

- Project Completion